We are focused on providing you with quality

products and unmatched customer service

and ensure that your project is running smoothly.

">

">We are focused on providing you with quality

products and unmatched customer service

and ensure that your project is running smoothly.

You can find more information about projects, processes

and company history in the presentation

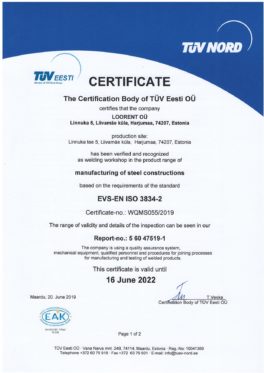

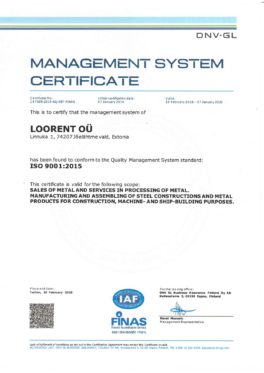

We have acquired a number of certificates to support the goals set and ensure high-quality production worldwide.

We conduct audits from distance, which give understanding of our business, fully via video. This reduces manual work and saves a lot of time and therefore grants customer satisfaction.

For audit please use the following form.

Oops! We could not locate your form.

Have a questions or want to know more about our company? We'll be expecting you.