We are focused on providing you with quality

products and unmatched customer service

and ensure that your project is running smoothly.

">

">

We are focused on providing you with quality

products and unmatched customer service

and ensure that your project is running smoothly.

You can find more information about projects, processes

and company history in the presentation

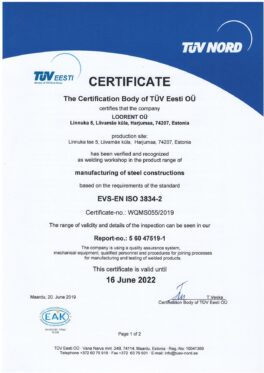

We have acquired a number of certificates to support the goals set and ensure high-quality production worldwide.

If you have a question, please, get

in touch

Oops! We could not locate your form.

When it comes to steel services, Levstal’s capabilities are impressively high, encompassing multiple different fields of work. Here are the five big operation types that Levstal can provide its customers:

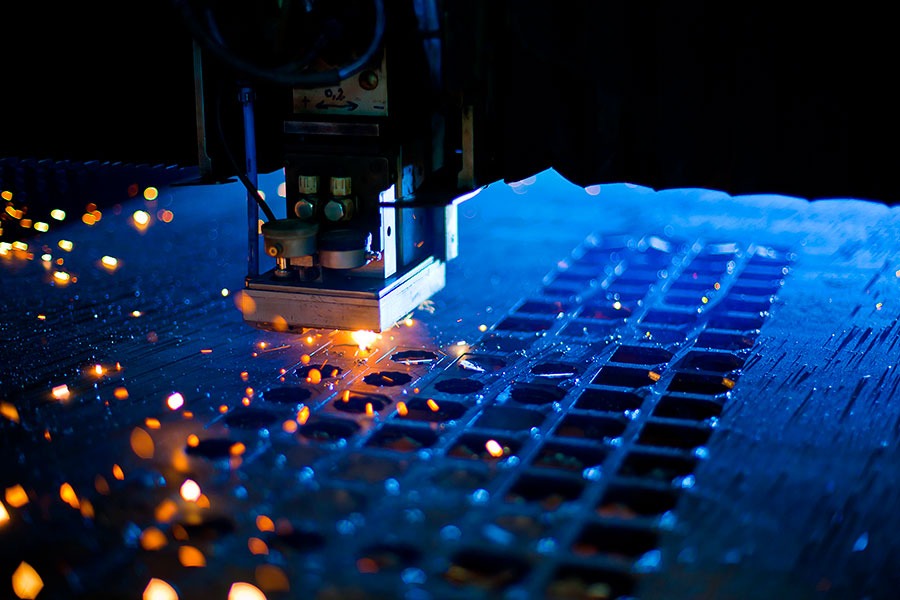

On its own, sheet metal cutting is a blanket term for a variety of different operations that are connected with pressworking in one way or another. The basic cutting operation usually explains the process of separating a metal sheet in a specific area with the use of a lot of force.

This force is applied to the metal sheet using two separate pieces of the machine – press and die. The die is the lower part of the machine, it is used to hold the metal sheet piece in the first place. The punch, on the other hand, is positioned above the sheet metal piece and is used to create the cut in the first place.

Levstal’s capabilities in terms of sheet metal cutting are vast and varied, offering operations on steel grades, stainless steel as well as aluminum.

Another relatively common operation with metal is sheet metal bending – a variation of the metal deformation process that uses various methods to transform the shape of the metal piece according to the desired specifications. Levstal’s capabilities in this field are vast, and appliances like CNC Aliko Press Brake 6000/630 allow the company to bend metal that is up to 6,000 mm wide and up to 5 cm thick.

Metal machining is another possible operation that Levstal can provide, with two of the biggest variations being milling and turning, as well as electro discharge machining and other services. All of the operations are performed using cutting-edge equipment, such as internal turning machines WHQ130CNC and WHN105CNC, among many others.

Three different methods above are not the only ones in the field, either – there’s also sheet metal welding, which is a process of combining several metal pieces together with the use of intense heat on specific parts of said pieces, provoking the fusion process when cooled. Levstal provides welding-based appliances to many different fields, including marine, construction, pulp and paper, hydropower, and many others. There are also several different material types that Levstal is capable of working with when it comes to welding – including iron, aluminum, copper, and stainless steel.

Finishing up with the variety of steel services that Levstal provides, we have metal painting. Levstal is capable of mass-painting various metal parts, and their capabilities include a paint area of about 1400 m^2, as well as a shotgun and a drying chamber with the dimensions of 5 m x 5 m x 15 m. Aside from painting, Levstal is capable of similar services – such as sandblasting, liquid spray painting, as well as powder coating (zinc coating and spraying, alkyd and epoxy coating, and polyurethane spraying).

Have a questions or want to know more about our company? We'll be expecting you.