House frame materials

Steel houses are not something you’ll think of when imagining a regular house, and it is for a reason. For quite a long time, there was a staple of wooden homes being used all over the place. After that, concrete homes pretty much became the norm, using not wood, but concrete as a frame of the house in question. However, there is also another type of house frame that can be used – steel.

It’s also fair to say that steel has its own advantages over both concrete and wood as a house frame material. For example, steel houses can benefit from steel being recyclable, among other advantages. While it is true that steel was considered a cheap and useless material a while back, times have changed and now steel is considered worthy of use as a frame material.

The basics of a house frame

There’s one thing that’s pretty much constant for every house – its foundation. It can be either a single concrete slab at the ground level or a basement (with said slab acting as a roof for the basement) – with brick/cement walls and a concrete floor. The foundation is typically where a house frame sits at, and there’s a number of different components that comprise a house frame when combined, in no particular order:

- Foundation. As we’ve mentioned before, the foundation is technically a part of a frame (since it’s supposed to support the frame in the first place), and it keeps the entire frame on top of itself.

- Studs. Framing components that are typically placed between the top and bottom plates, considered one of the more common wall elements.

- Gable studs. Vertical components of a frame, with the main purpose to transfer the weight of a roof to the double plate.

- Joists. Horizontal components that support a lot of other parts of a building, and usually are covered with some type of subflooring.

- Subflooring. A combination of several components – floor joists, sill plate, and deck sheeting. A finished floor of a house is laid on top of the subflooring.

- Struts. Supportive components that are placed in-between studs to increase the entire construction’s reliability, and to keep the spaces between studs consistent.

- Plates. The top and bottom plates are two equally important components that, when combined, form the basis of a wall – its top and bottom parts, respectively, with studs running in-between the two. The upper plate is often called a double plate, and the lower part of a frame is a sill plate or a sole plate, more often than not.

- Rafters. A supporting component of a house frame, the rafter is a diagonal piece that rests against the double plate and the tie beam – its main purpose is to support the entire roof.

- Tie beams. A supporting horizontal component that is used to connect two rafters to each other (or to connect a rafter to a truss).

- Trusses. Another supporting structure that’s supposed to distribute the weight of a roof over a wide area and is usually comprised of a horizontal “web” of beams.

Common house frame materials

Now that we’re done going over the basic elements of a house frame, we can move over to different framing materials. Since steel houses are the main topic of this article, we’ll go over those in a bit more detail, but for now, we’ll review two of the remaining material types – wood and concrete.

Wood is the oldest and the most common material for a house frame most people can think of. It has been around for a while, going back as far as millennia, to some of the first human-built houses in the first place. It is a material that always was easy to reproduce and source to build something, and the abundance of trees more than made up for it.

Since there are quite a lot of different types of wood that can be grown and/or used as a material for your house, it’s also important to mention that Acacia is considered one of the best, if not the best wood type to use as a material for house building, furniture building, and so on. However, while the number of houses built with wooden frames is still quite high, timber conservation efforts had a significant impact on this number already, and it might become even less common in the near future.

Concrete is another material that can be used in construction – although, its more common use case is to use as a foundation material. At the same time, it is possible to have an entire house built with concrete, with an entire house becoming one giant house frame.

Concrete as a frame material allows for quite a lot of unusual design choices, and it’s also a flexible material, in general – when it comes to both shapes and protective properties. One variation of concrete that is particularly popular is ICF or Insulating Concrete Forms.

Now that we’re done with both of those materials, it’s time to look at what steel houses can offer to you in comparison.

Steel houses and their advantages

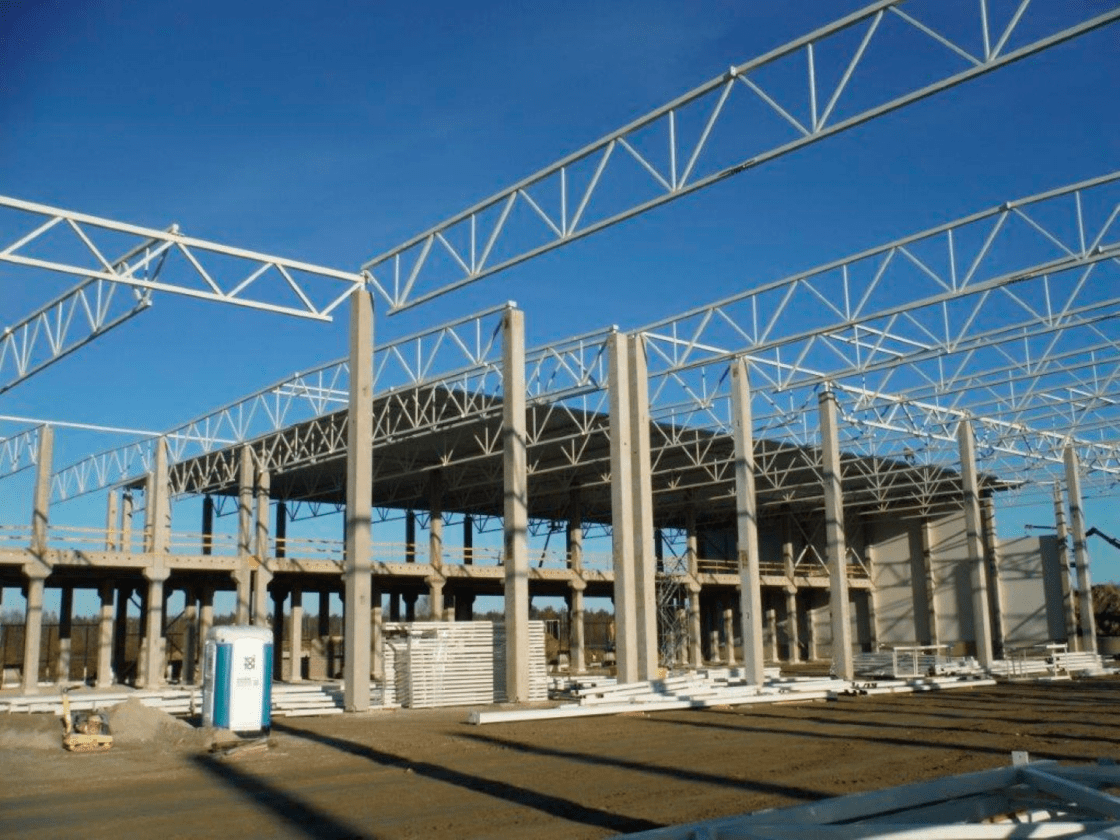

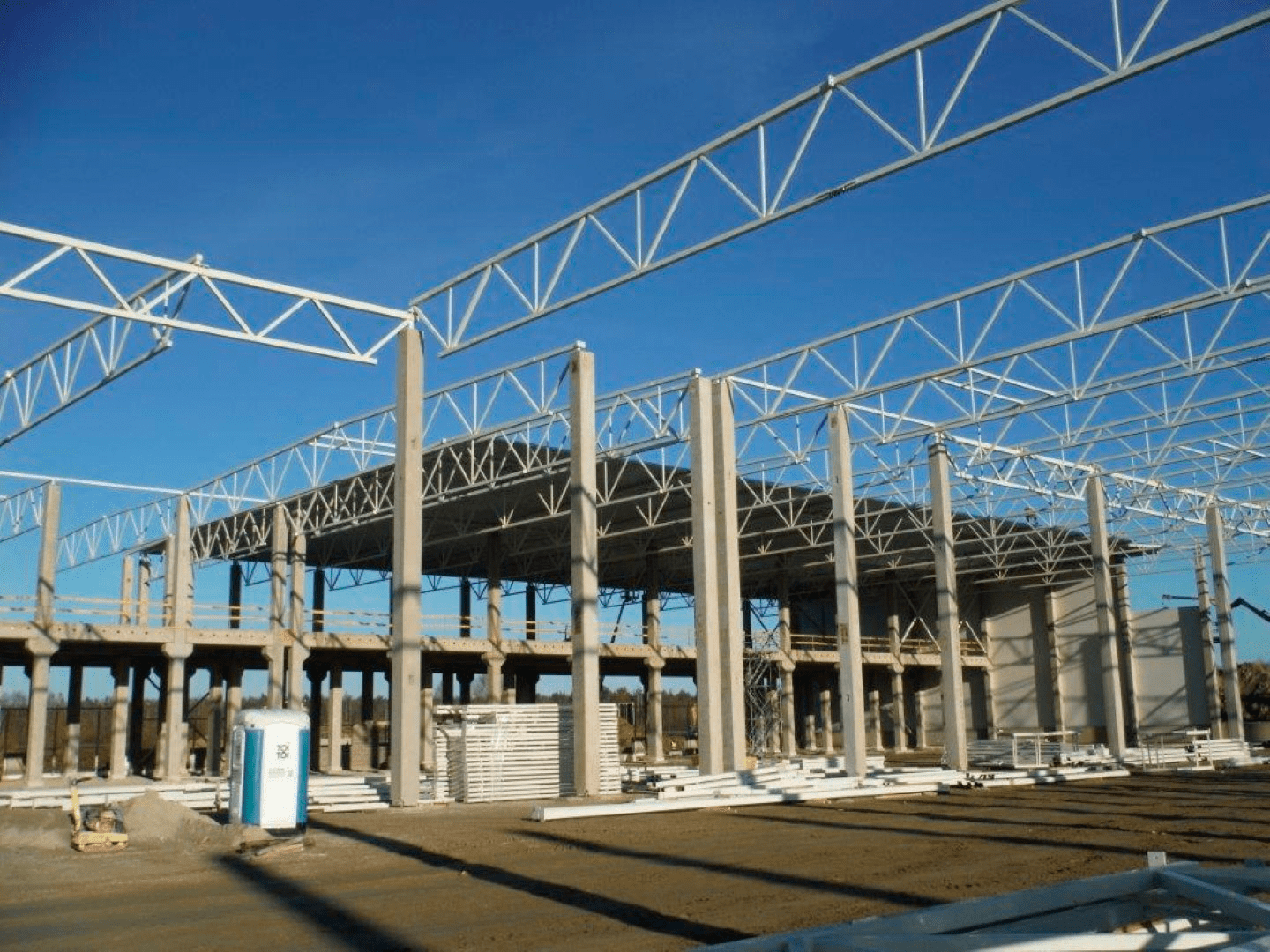

It is fair to say that frames for steel houses are created more like their wooden alternatives – meaning that steel frames are constructed from various parts and components, and not molded or poured into (as you would have to do with a concrete-based frame).

Since the frame component list we’ve mentioned above is more suitable for wooden structures, it’s fair to say that frames in steel houses use various types of beams in place of studs, rafters, joints, and other components – including, for example, I-beams. The price difference between wooden and steel houses is also quite small, in most cases.

Steel frames, due to being constructed from the material itself, are waterproof, fire- and earthquake-resistant, and quite durable. It is worth mentioning that all of these parameters and attributes are only talking about the steel itself, and does not affect anything that is attached to a said frame (drywall, for example).

A steel house frame is also easier to build from the ground up when compared with wooden frames, and the overall weight of a steel frame is smaller. Additionally, some parts of a steel frame could be molded, or customized in some other way. It’s also way easier to recycle and reuse steel frames, which is a big plus when compared with aging wood.

However, steel is also not perfect, it has its own disadvantages when used as a material for a house frame. For example, it’s not energy-efficient whatsoever, it conducts heat quite fast, leaving the inside of a house colder than it could’ve been in, let’s say, wooden houses.

Additionally, the aftereffects of thermal bridging can also create stains of colder portions of your walls, increasing both air conditioning and heating bills for a house owner. There are ways to counteract that, though. You can wrap an insulation board around your steel beams, or do cavity wall insulation in the first place. There is also an alternative of creating a hybrid frame with both wood and steel, combining the advantages of the two, but it’s not as common as other material types.

Conclusion

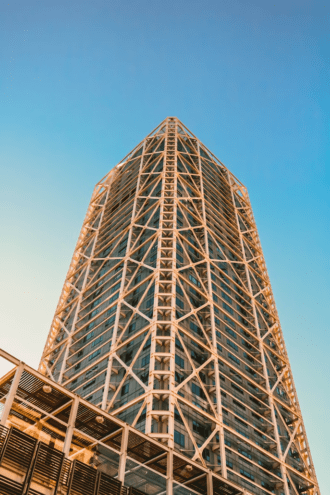

It’s safe to say that steel is the “future” when it comes to materials that you can build a house from. Steel’s capability to resist some of the worst natural elements is pretty much unmatched, and steel is the most recycling-friendly material so far, which is a massive factor in the current day. This is the reason why steel houses are the future of the industry, and steel companies would have to be up to the task.

The steel construction industry is highly competitive already, and it does not seem like there’s going to be a decrease in demand, either. On that note, it’s a good time to remember one of the more prominent steel companies on the market – Levstal. It’s a highly versatile construction company that offers a lot of personalization to its clients and has clients all over the world – including North America, Japan, England, France, Belgium, and so on.