Introduction

The construction industry as a whole is supposed to produce strong, durable, and resistant structures of all shapes and forms. In this context, it only seems appropriate that metal is used on a regular basis in the construction industry to create a large variety of structures and shapes.

However, it would not be fair to say that all of the tasks in the construction industry are performed using the same type of metal. In fact, there are many different variations of metals that are used for specific purposes, be it tubes, street lights, construction plates, heat pumps, and more.

While the overall number of metal variations used in construction all over the world is extremely large, it is still possible to figure out four main types of metal – the ones that are considered the most popular in this particular industry. These four metal types are:

- Stainless steel;

- Aluminum;

- Carbon steel;

- Copper tubing.

Each of these metal types has its own list of use cases, which we are going to discuss below.

Stainless steel

The combination of corrosion resistance, stain resistance, and durability made stainless steel a great choice of a construction metal many years ago – and it is still considered one of the best materials to this day. In fact, there are multiple structures made with the help of stainless steel that are still standing to this day – despite the fact that they were constructed many years ago.

As an example, there is the Chrysler Building – built as far back as the year 1930, it still stands firm in New York, making it one of many testaments of why stainless steel is so popular.

The metal itself is strong, reliable, and durable. It is an alloy of multiple different metal variations, with the most common variation being the one called “301” – a grade of stainless steel that is easy to weld and is also ductile. It is used for handrails, drainage components, roofing, all kinds of metal construction structural applications, and more.

Of course, there are many other grades of stainless steel – the grade of this metal is determined by the amount of each of its components in the final alloy. The aforementioned grade “301” is just one of many variations of stainless steel that could be used.

Aluminum

Aluminum is another material that has been around for a while and has a myriad of different applications. With its main advantages being ductility, resistance to corrosion, and high conduction, it is not that surprising to see aluminum being used for outdoor signage, windows, doors, street lights, etc.

Aluminum is also processed in multiple different forms – be it castings, sheets, tubes, and such. All of these are then used to create bicycles, automobiles, marine vessels, trucks, and other types of transport. Aluminum’s usefulness does not stop there, too – it is also used for handles, roofs, walling, HVAC ducts, and so much more than that.

Carbon steel

When it comes to sheer strength, it is hard to imagine a metal alloy that is as widespread as carbon steel – another metal alloy that is mostly used in situations when there’s a need for a hard and strong metal structure. For that exact reason, it is often used to create parts of the structural framework, rectangular tubing for bridges and trailer beds, highway construction metal plates, and more.

Carbon steel is also used to make HSS (hollow structural sections) and rebar. It is a combination of iron and carbon that can also change some of its specifications depending on how much or how little carbon is present in the alloy.

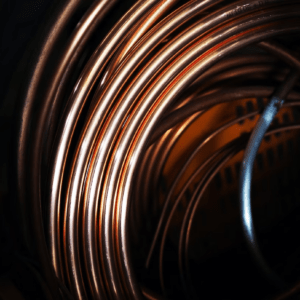

Copper tubing

Piping and tubing are also a rather popular part of the construction as a whole – and this is where copper shines the most. Copper is often used as a primary material to create all kinds of pipes for construction purposes, and there are two variations of copper tubing that could be utilized.

Soft copper is used for heat pumps and refrigerant lines (HVAC), while rigid copper is more about tap water pipes inside buildings (both cold and hot water). Copper is resistant to corrosion, recyclable, but also malleable and ductile – this combination of parameters makes it one of the best choices for tubing/piping from all of the metal variations.

Other metal types

While these four variations of metal are some of the most popular options for different parts of construction as the industry, there are also many other metal types used on a regular basis for more specific purposes.

For example, lead is still used as a material for metal construction in some cases – most of the time it is used for roofs, windows, downpipes, cornices, and so on. Since lead by its nature is a toxic material (if absorbed into a human body) that is also considered a “heavy” metal, its usage is getting lower and lower (additionally, it is also somewhat expensive to use in large quantities).

One of the biggest use cases for the lead right now is traditional buildings. It is also used for conservation purposes, as well as many smaller domestic applications, such as valley gutters, chimney flashings, and so on.

Other examples of different metals used in construction are iron (in the form of pig iron, cast iron, or wrought iron), many other variations of the aforementioned steel (weathering steel, galvanized steel, etc.), titanium alloys, and many other examples.

Conclusion

Metal is one of the most important materials in construction as a whole, and there are many variations of said metal – different types of metal, different alloys, and so on. In this article, we tried to cover some of the more popular metal types, as well as their use cases.