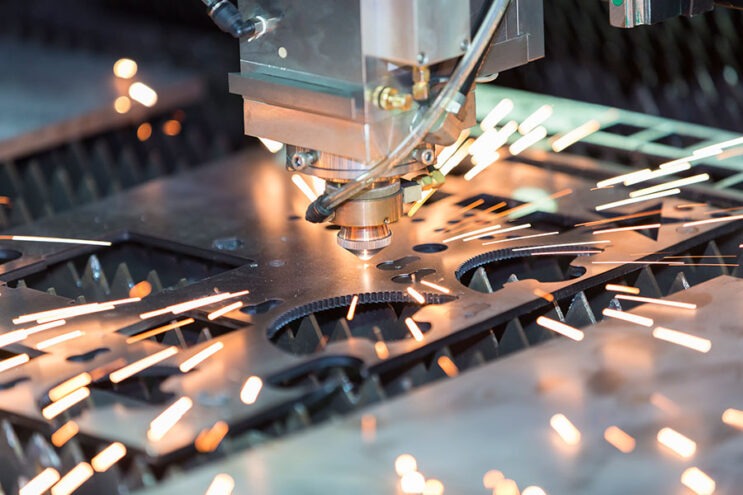

Sheet metal cutting as a whole is a rather sophisticated process that uses several different types of cutting appliances, as well as multiple cutting methods to be able to accommodate a variety of different use cases. There are four popular sheet metal cutting types – waterjet cutting, plasma cutting, oxy-fuel cutting and laser cutting.

Each of these different cutting types are more suitable for their specific niche, in which their abilities are unparallelled. For example, laser cutting is the undisputed leader when there is a demand for precise and accurate cutting as a whole. The overall popularity of laser cutting eventually spawned its own sub-branch with small lasers that can be used by people with specific hobbies within their own homes.

However, the main topic of this text is still the regular laser cutting process for industrial purposes, offering its users the capability to create complex shapes and details that are close to impossible to produce with other sheet metal cutting methods.

Laser cutting basics

The precision itself is possible thanks to the combination of the laser optics and the computer numerical control (often referred to as CNC) – a motion control system uses the necessary pattern and follows it with the laser itself. Laser cutting as a process is made possible by focusing the high-powered laser output with the help of various optics. The laser in question is aimed at the material, focusing its power on a very small spot of the material, which allows for an unparalleled level of precision and effectiveness.

Laser cutting also leaves no cutting edge that can be contaminated with the leftover material (its biggest advantage over a more traditional mechanical cutting). The laser beam itself also does not wear out with time, and has a very slim chance of warping the edges of the material in question since the heat-affected zone of a laser cutting process is impressively small.

At the same time, laser cutting also has its limits, and it is more suitable for precise work rather than cutting thick metal sheets. While some of the more modern laser machines are capable of coming close to the capabilities of plasma cutting when it comes to material thickness, both the overall cost of such a machine and the amount of energy needed for it are still far greater when compared with plasma cutting as a process.

Types of laser cutting

As for the laser types that are commonly used in the process, it is possible to segregate three major ones:

- CO2

- Nd

- Nd:YAG

The CO2 laser is a more common or standard variation of laser cutting, it can be used for most of the cutting processes that involve lasers in the first place, and it can also be used for engraving or boring. This particular laser type is centered around either passing a current through the gas mix, or by using a radio frequency energy. The former approach is called DC-excited, and the latter can be referred to as RF-excited.

The DC-excited approach is older and requires electrodes inside of the cavity, creating a risk of either general erosion or plating of electrode material on optics. The RF-excited method is relatively new and has already gained more popularity than its competition, mainly because of how it is constructed – RF-excited method only needs electrodes on the outside of the cavity, eliminating the possibility of erosion and other issues.

The CO2 laser has a fairly large list of applications and can be used for many materials, including, but not exclusive to plastic, wood, stainless steel, wax, aluminum, titanium, and even something as fragile as paper or fabric. As for the Nd and the Nd:YAG laser types – it should be fairly obvious how similar these two types are in nature, with their biggest difference being application.

The Nd type is more suitable for tasks that require the combination of high energy and low repetition, while the Nd:YAG laser has a specific number of use cases with massive power requirements – commonly used for either engraving or boring for specific materials, such as ceramics or some metals.

It is also important to mention how laser cutting performance can also be affected by other factors that are not just the cutting type. For example, some of the more commonly used CO2 lasers may have different gas flow types – and each gas flow type tends to affect the overall performance in some way. There are several different types of gas flow that are the most common for CO2 lasers – slab, transverse flow, as well as slow or fast axial flow.

At the same time, the process of laser cutting does have to have some sort of cooling due to the overall amount of heat being dispersed via both the generator and the optics – with water being one of the most common coolants that can be circulated via a heat transfer system.

Water can also be used in a different way when it comes to laser cutting – which is where a “laser microjet” comes in. It is a laser type that is guided by a low-pressure water jet. This particular technique has a number of advantages when compared with the regular “dry” laser cutting, such as the immediate removal of debris after the cutting process, as well as the overall cooling for the material in question. Other advantages include the ability to cut in any direction, improved dicing speed and the parallel kerf capabilities.

The topic of laser cutting types also has another “honorable mention” type of laser cutting – a fiber laser. It is an up-and-growing type of laser cutting that is relatively new but already gaining traction within the industry as a whole. It uses an entirely new approach to laser cutting with the help of a solid gain medium, compared with the previously mentioned liquid or gas to kickstart the laser itself.

Fiber laser uses the so-called “seed laser” to produce the beam itself, and then it gets amplified with the help of a glass fiber. It has an extremely small wavelength that is up to a hundred times smaller than all of the CO2 lasers, which makes it extremely useful for reflective metals, among other advantages.

Speaking of advantages, fiber laser type has a rather large list of those, including benefits such as little to no maintenance, greater energy efficiency and the aforementioned ability to work with highly reflective materials (brass, copper, etc.). Fiber laser also has cheaper operational costs and thus is more cost-efficient than most laser cutting types – despite the fact that it uses rare earth elements such as neodymium, erbium, etc.

On the topic of laser cutting methods, we can also mention pulsed lasers as one of the alternatives to constant laser cutting. A pulsed laser provides a burst of energy with high power for a short time period – extremely useful in various piercing purposes, and it can also be used for materials that require an extremely low cutting speed (so that the constant heat from the laser itself would not melt the entire workpiece)

It is worth noting that the majority of industrial lasers already can use pulsing (or continuous wave) via their NC program control. There is also a variation of this method that is called double pulsing, which uses pulse pairs for better cut quality and easier material removal.

Machine configurations for laser cutting

As we have mentioned before, laser cutting uses CNC to direct the laser beam, allowing for the unprecedented precision and efficiency. However, there can be several different ways to configure machinery for these specific purposes. It is possible to discern three different types of machine configuration for these purposes – flying optics, moving material and hybrid.

Flying optics include a combination of dynamic cutting head and a stationary table with the metal piece on it. As the name suggests, the only movable part with this method is the cutting head that can travel both horizontally and vertically for cutting purposes. Most of the time there is no need for material clamping to keep the metal piece in place since the flying optics cutters are enough to keep it in place.

This type tends to be the fastest out of the three, since it is at its best when used with thinner material types. At the same time, it is important to remember about how the laser beam’s capabilities change depending on how close it is to the workpiece – resulting in either far field cutting or near field cutting. One of the most common controlling methods for this is the usage of adaptive optics or collimation (the process of accurate line of sight adjustment). Using a constant cutting head height is also an option.

Moving material, on the other hand, is the exact opposite – since it has a stationary cutting head and the only part of the machine that moves is the one that holds the metal piece. It has the benefit of a static beam length, but it also is the slowest method out of the three due to the need to move the entire workpiece for even the smallest cutting operations.

A hybrid laser cutting method is the combination of two of the previous methods, as the name suggests. This system is an attempt to receive the benefits of the two completely different cutting methods while covering their weak spots. As a result, both the table with the metal piece and the cutting head are capable of moving along their own axis (the usual combination is the X axis for the table and the Y axis for the cutting head). The result of this method is a simpler beam delivery system with a more constant laser beam when compared with the flying optics method, and it also has a higher capacity per watt due to the reduction in power loss for the delivery system.

Other notable machine configurations that are not as popular include five-axis or six-axis machinery that are rather common when it comes to cutting parts of the formed workpiece – these machineries are also extremely complex, with many laser beam orienting methods to ensure that all of the necessary parameters are achieved, such as nozzle standoff, focus distance, and more.

Laser cutting and Levstal

Laser processing of metal is essential for high precision work. Levstal provides a variety of different laser cutting operations that can be performed with our Trumpf TruLaser 5060 Laser machine.

Features: black metal and stainless steel up to 25 mm thick, aluminum sheet 12 mm.

Advantages of laser cutting:

- reduction of risk of metal deformation

- high quality of cutting

- cutting speed

- economical use of material

- moderate service cost