There are many wood processing facilities in this industry that are focused mostly on transforming these logs into other material types, but this process usually involves a lot of machinery due to the sheer weight of the material in question. A conveyor of sorts is almost a necessity for these processes – such as a log belt conveyor that Levstal helped with.

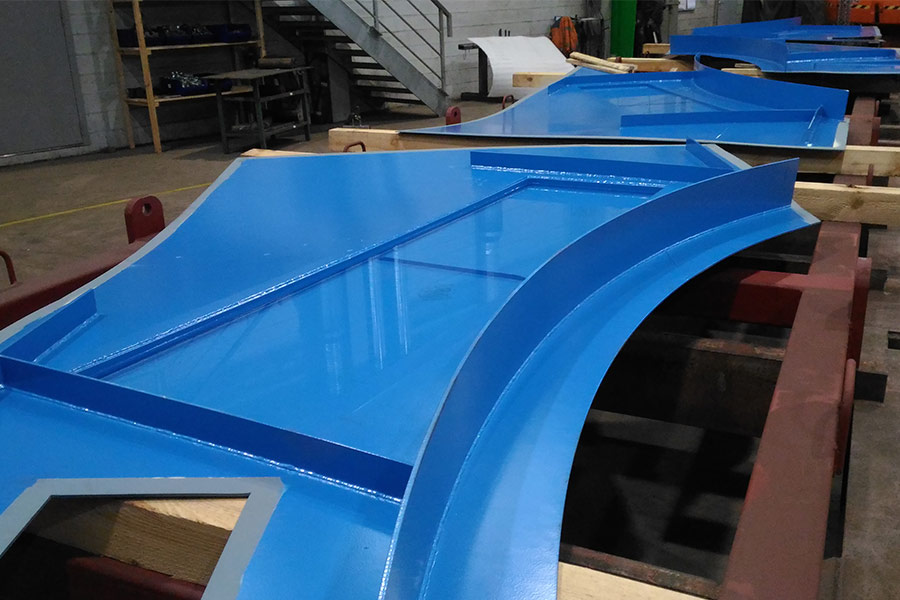

In this project, it was up to Levstal to manufacture and deliver a number of parts for the log belt conveyor for a client in Finland. The list of parts that Levstal had to produce includes geer rim covers, roller conveyors, log belt conveyors, drum discharge conveyor and chopper infeed chutes. The entire scope of the manufacturing process was used for this, including operations such as NDT testing, welding, rolling, blanking and assembly. All of the elements were also painted and shipped by Levstal.